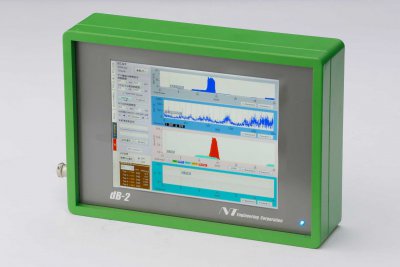

Vibration monitoring unit dB-2 Ver.2

Monitor machining on behalf of the machine operator.

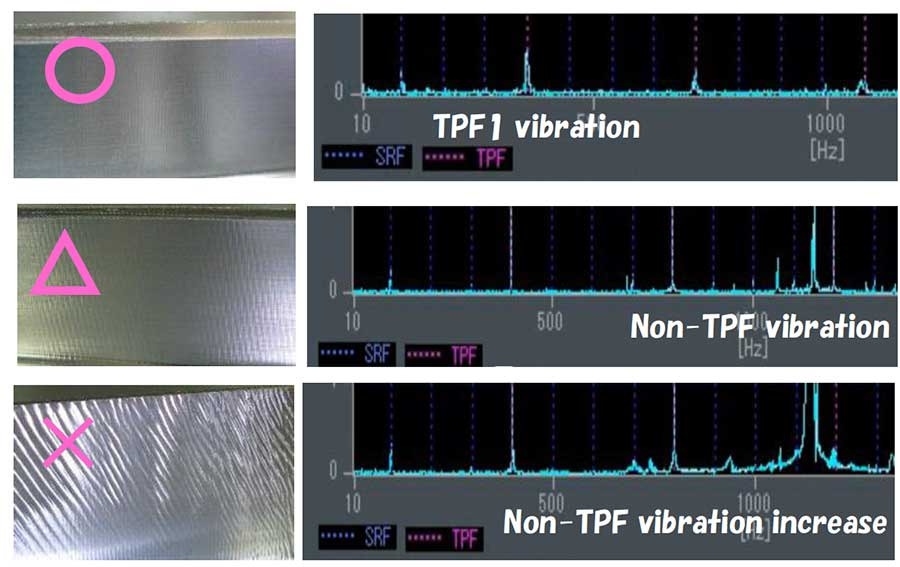

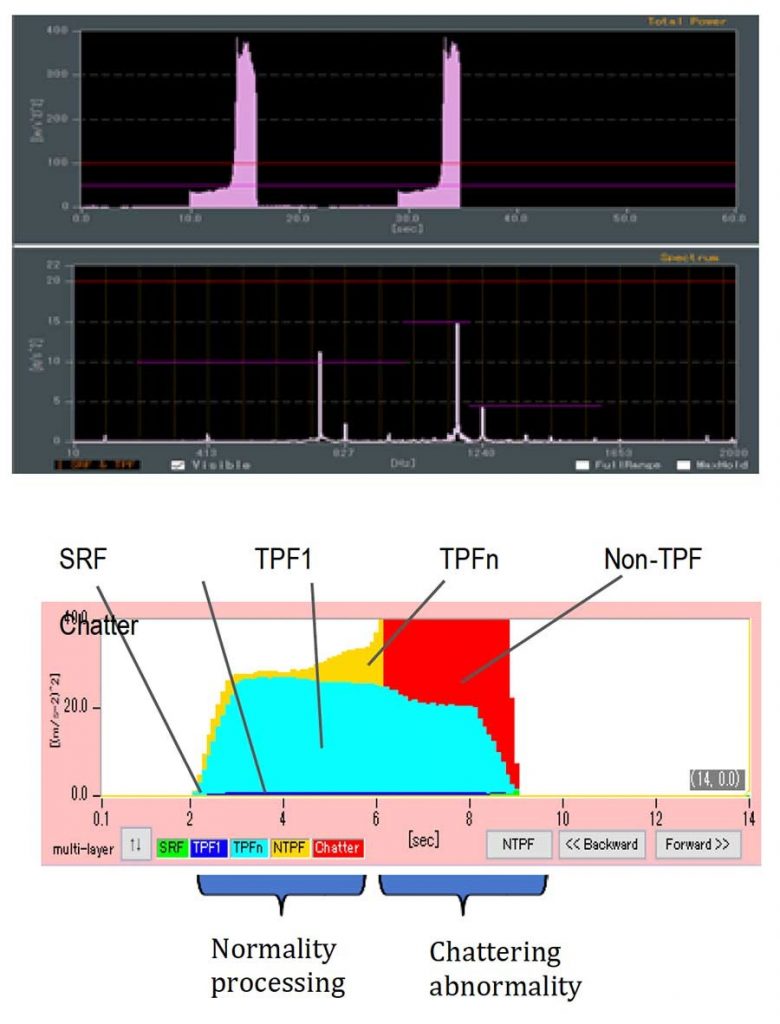

The machining state is distinguished by 5 colors like the signal of a traffic light.

Product features

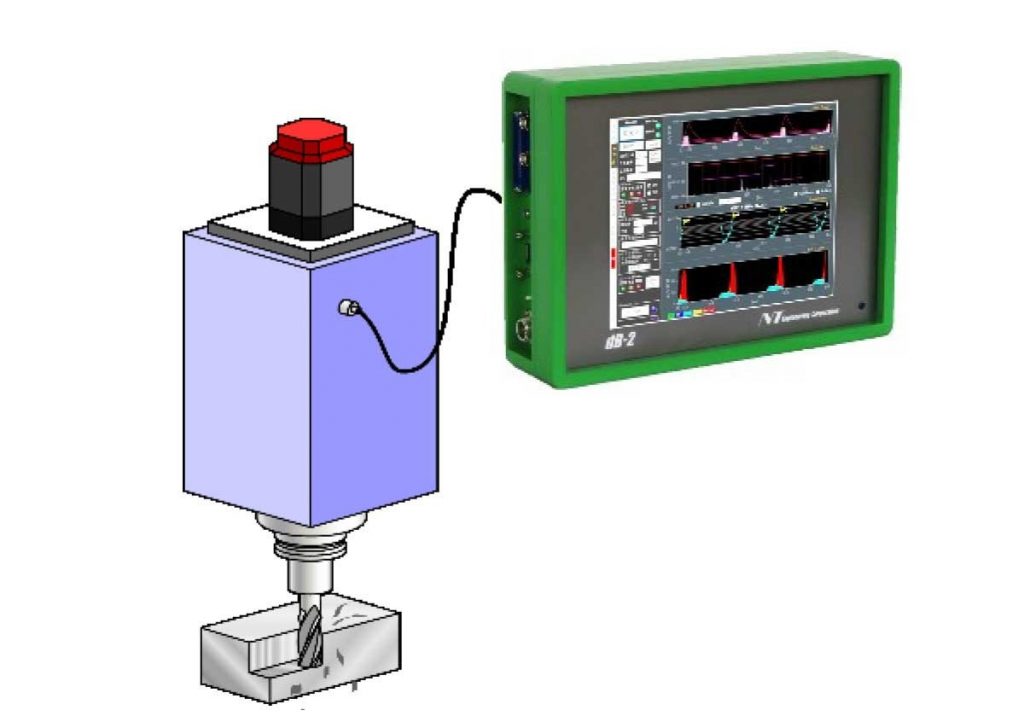

The clue to knowing the processing state, is to focus on the processing sound and vibration of the same source. Delicate and accurate discrimination can be made by looking at the vibration frequency calculated by Fourier transformation. The processing status is automatically monitored in the “TPF” domain. Like a traffic light, it identifies the processing state and captures signs and abnormalities along with color display. dB-2 monitors machining with total power and frequency spectrum.

Advantage of introduction

By load current monitoring, chatter may be overlooked. If you take the machining vibration including a lot of machining information, you can understand the state as if you hear the machining sound.

The best machining information is not only by the strength of the machining vibration but also by Fourier transform frequency. Machining vibration frequency is linked to machining information.

The machining vibration is automatically monitored macroscopically by dividing into two parts, the passing frequency of the tool “TPF vibration” and the other “Non-TPF vibration”.

Avoid also troublesome threshold setting in relative comparison.

Like a traffic signal, displayed in 5 colors that clearly show the processing status.

The red color shows a chattering abnormality, indicating the need to stop processing or change the conditions.

The red color shows a chattering abnormality, indicating the need to stop processing or change the conditions.

The cutting vibration is displayed in real time with the strength of the time series. The machining vibration is used as a frequency spectrum to recognize and monitor the status of machining quality.

In-process monitoring that detects abnormalities at an early stage and avoids defects by taking corrective actions.

Machining monitoring based on machining sound and machining vibration of the same source is “Means for Visualization of Machining”

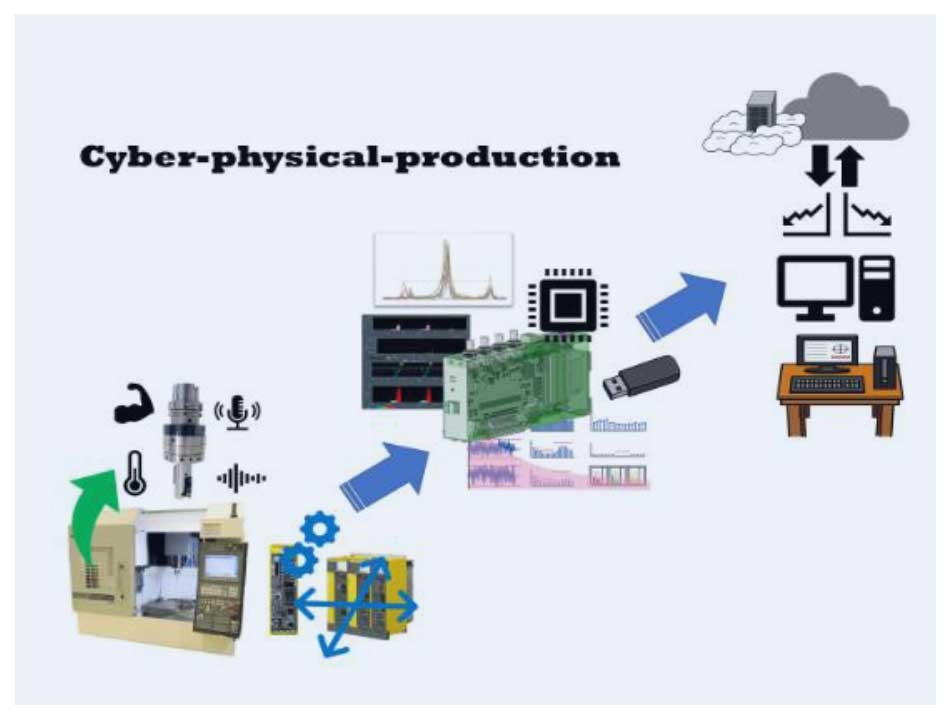

This device is a milestone product to support the digital twin “IoT of machines”.

Edge device of intelligent machine

dB-2 Controller

Number of measurement channel terminals:

2ch input/only one sensor is attached

Screen size

10 inches (with touch panel)

Size:

W:320mm×H:245mm×D:80mm

Weight:

4.5kg

Power connector included

Power supply: AC100V-240V

input/output signal

DC24V(Only the connector is attached and the wiring must be arranged by the customer)

USB connector terminal

VGA connector terminal

With LAN connector terminal