The closed loop directly controls the hydraulic pressure.

Can be processed like a crowning shape.

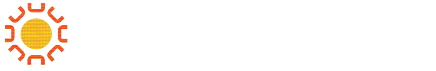

This device is a correction system that directly controls the hydraulic pressure from a dedicated power unit with a servo valve and controls the hydraulic pressure as correction power.

Controls hydraulic pressure from 0 to 15 MPa. The output hydraulic pressure from the servo valve is controlled by a box separate from the dedicated controller.

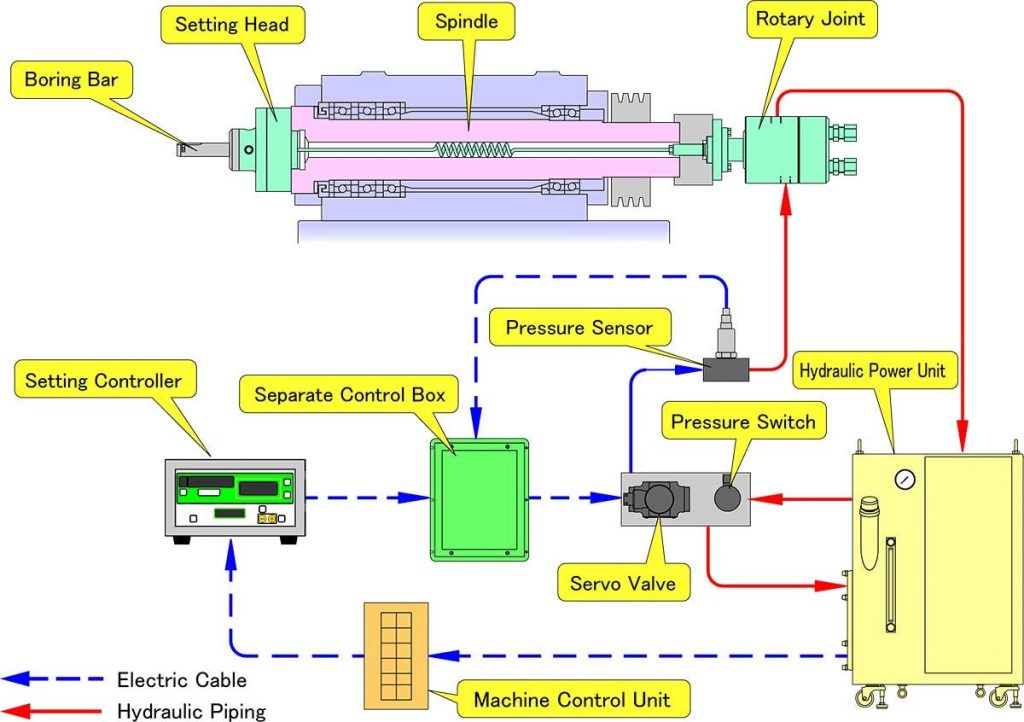

The compensating head unit performs highly precise compensating displacement in micron units in combination with a membrane head for hydraulic direct with less stick slip.

With this system, not only straight holes but also finer up/down control of the cutting edge (oil pressure increase/decrease control) allows taper shapes such as piston pin holes and connecting rod holes and virtual crowning shapes to be machined from one direction with one stroke. Is possible

Compact and energy-saving hydraulic direct control system.

The pressure proportional control valve controls the hydraulic pressure output from the large-capacity pneumatic hydraulic cylinder with the compensation controller. The oil pressure moves the membrane correction head part with high precision and fineness.

Compared to the electric motor type, it was possible to make contact and aggregate the components.